An introduction to streamlining and automating your business processes

But, as with so many things in life, once you transition to a better, less manual way of doing things, you may wonder why it wasn’t done sooner.

Indeed, many of your competitors have already taken the leap on streamlining and automating business processes.

According to a study by The Economist, nearly half (48 per cent) of UK businesses describe the use of automation as “extensive”, whilst 35 per cent describe the organisation’s progress with automation as “moderate”.

It’s not too late to join the movement. There’s lots you can do to improve the productivity of your business and this guide will help you get started.

What factors affect the automation of business processes?

Technical feasibility

The bottom line is that workplace automation – specifically automation incorporating things like emotional and social reasoning – is still nascent. Despite marketing hype, there’s simply a lot that software and machines can’t do.

That said, there’s a lot of potential for adapting and automating at least a portion of even the most high-performing jobs. According to McKinsey, for example, more than 20 per cent of a CEO’s working time could be automated using current technologies.

While any serious examination of automation technologies needs to be realistic, there is a lot of potential right now for cost and labour saving.

Implementation costs

Cost is, of course, central to any business decision making. Like any other choice, the decision to implement automation should be analysed with a cost-benefit framework.

Consider the costs around the technology, too. Cameras and sensors, for example, will be needed for any activity requiring sensory perception, while mobility requires wheels and fuel.

And, like Charlie’s dad in Charlie and the Chocolate Factory being hired to repair the machine that automated his old job, automation often involves hiring new staff to maintain and run the new systems.

Labour markets

Many industries have a high automation potential (restaurants, for example). The reason they’re largely unaffected is due to the cost of labour being notably less than automation and technology.

There’s no reason to implement automation for its own sake – and, especially for the foreseeable future – it’s not necessarily more affordable than old-fashioned elbow grease.

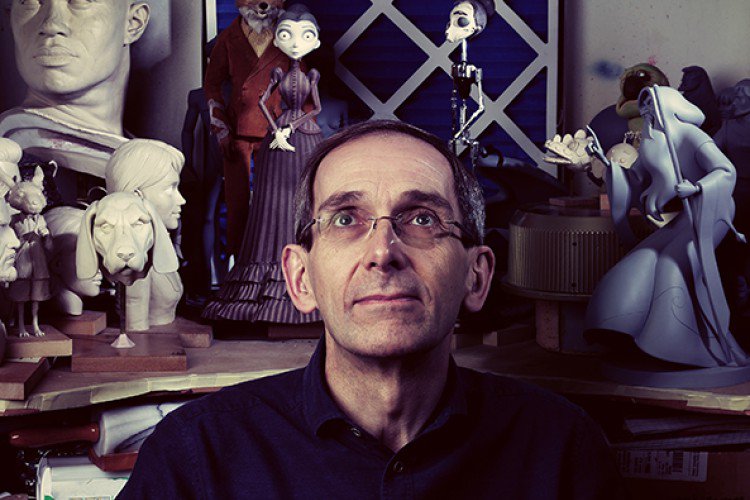

Peter Saunders used 3D printing to automate how puppets are moulded at Mackinnon & Saunders

“Don’t be afraid of new technology. Keep an open mind about the potential it could give the company.”

Peter Saunders, co-founder of Mackinnon & Saunders

The cold hard facts

Interestingly, there’s been a subtle change in the rollout of automation in the UK. According to the ONS, the proportion of jobs at a high risk of automation actually decreased slightly between 2011 and 2017, from 8.1 per cent to 7.4 per cent.

What has increased, however, is the proportion of jobs with a low to medium exposure to automation. Automation at work is much more nuanced than is often presented. It’s rarely all or nothing.

Common mistakes with implementing automation

Don’t assume that everyone will understand

To you as the business owner or leader, automation or introducing a process to streamline something might make intuitive sense. But to folks on the ground, it might be confusing or threatening.

Many employees don’t think about the business strategically (and, to be fair, they aren’t paid to). Their focus is on day-to-day operations. They have a groove and a rhythm and may react in an instinctively negative way to change.

For automation of any process to be effective, these feelings must be addressed. It helps to understand the nature of this resistance. As Paul Lawrence, a pioneer in organisation design, noted in the 1960s: “What employees resist is usually not technical change but social change.”

This remains true. People aren’t solely concerned with the technicalities of change – but also “the change in their human relationships that generally accompanies technical change”.

Not automating the right things

Just because you can automate or streamline, doesn’t mean you necessarily should. A classic mistake businesses make is trying to automate things that either aren’t good candidates for automation or simply aren’t cost-effective.

Instead, start simple and build out. In the first few instances, target things that’ll give you value straight off the bat.

Automated customer support tools, for example, are a well-developed market and can help you automate routine customer queries and buyer journeys. Forecasting tools can take a lot of the manual work out of your financial planning.

Not having the technical skills

The value of any product or commodity isn’t intrinsic to it. Its value is unlocked by some sort of skilled worker or person using it correctly. For example, you can buy a beautiful Les Paul guitar but if you’re unable to play it’s just an ornament.

The same principle applies to automation tools or any processes you introduce to your business. Workers need to have the skills necessary to use it properly.

Make sure you know what skills your team has and, crucially, what skills they’ll need to effectively use any tool you’re considering.

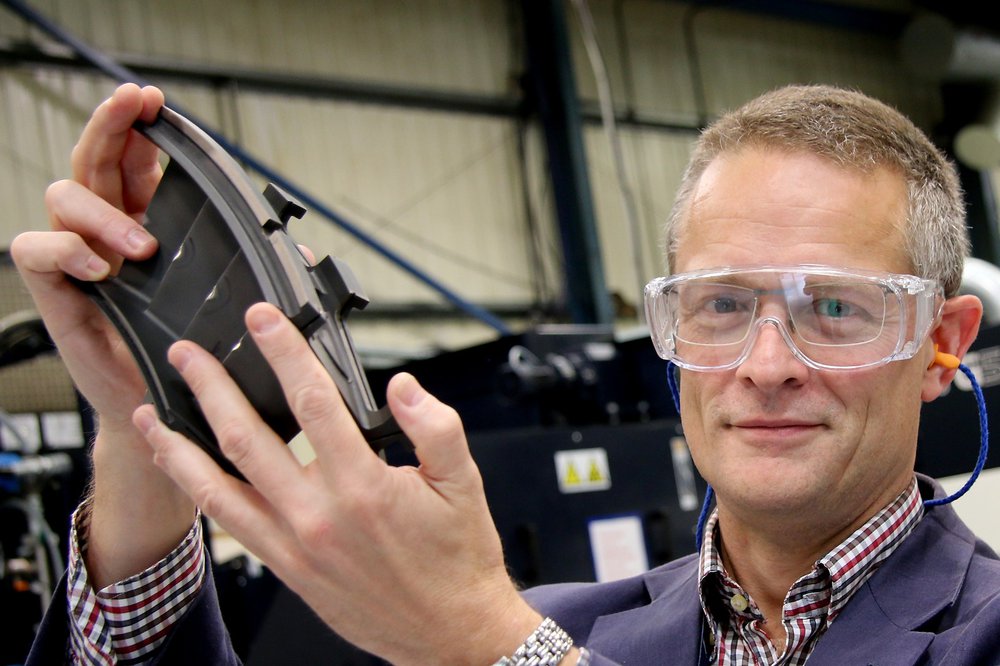

Tom Simmonds looks carefully at anything that's taking the business away from what it does best

“You intrinsically know if you're running a business where your pain points are, the things that niggle you. Write down a list of all the things that take you away from what you do best, and then see what software you can buy to address that.”

Tom Simmonds, chief executive of AllSaved

The cold hard facts

According to the government, the adoption rate of automation technology among UK SMEs is only four per cent. Unless you’re a behemoth like Amazon or Domino’s, you likely don’t have the capital required to automate whole supply chains or processes. But that doesn’t mean it’s not possible to apply some automation tactically. Many automation solutions can be bought off-the-shelf and will allow you to out-compete local businesses and match international competitors stride-for-stride.

Quick wins for improving automation

Involve staff in the process

If you’d like to hit the ground running, staff buy-in is vital. A good way to secure this buy-in is by involving employees in the decision-making process.

Of course, you don’t want decision-making by committee – and ultimately the choice lies with you. But, employee input can (and should) direct your choices.

Implicitly, many workers know what aspects of their jobs can be improved through automation. Almost two-thirds (59 per cent) of employees say automation could save six or more hours a week if the repetitive aspects of their job were eliminated.

Make automation relevant to employees’ jobs and ask them where it can be used to improve their work.

Set up systems that integrate

Your business is a complex entity, consisting of different people, tasks, processes and products. So there is no one size fits all when it comes to choosing the product or tool for the whole company.

What’s more likely is that you will need to implement a patchwork of different things. Think carefully about having sustainable tools which grow with your business and ensure different systems can integrate with each other.

Forecasting tools

Automation isn’t new. What is new, however, is the increasing capability of machines and computers to perform more complex cognitive activities.

For business leaders, this is an exciting development. Automation is no longer just about labour-saving technology. There exists a whole range of off-the-shelf products and tools that help business leaders produce better forecasts.

This type of automation is particularly easy to implement since it only affects you and other senior people in the company. There’s no particular need for widespread buy-in from employees.

Andrew Churchill urges other leaders to look at how analysis could run in real-time

“Whilst they are very powerful, spreadsheets are dumb, they are not real-time and they are out of date the moment you produce them. The opportunity with newer business information systems is to run all of that analysis in real-time.”

Andrew Churchill, executive chairman at JJ Churchill

The cold hard facts

According to PwC, automation will be the “main contributor to the UK's economic gains between 2017 and 2030” and will “stimulate consumer demand by 8.3 per cent”. Automation allows businesses to offer a greater degree of personalisation and a greater choice of products at more affordable prices.